Soaring with Precision: The Evolution and Future

Flight Maintenance

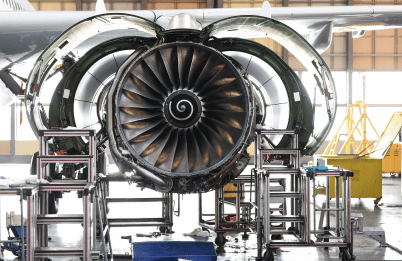

In the dynamic world of aviation, where safety, efficiency, and sustainability are paramount, flight maintenance stands as the bedrock. Far from being a static discipline, aircraft maintenance is undergoing a profound transformation, driven by technological advancements that are reshaping how we inspect, repair, and overhaul these marvels of engineering. This article delves into the critical role of flight maintenance, the cutting-edge technologies revolutionizing the field, and what the future holds for this vital sector.

The Unseen Pillars of Airworthiness

Every smooth takeoff, comfortable flight, and safe landing is a testament to the meticulous work of flight maintenance professionals. Their responsibility extends beyond mere repairs; it encompasses:

- Ensuring Airworthiness: Adhering to stringent regulatory standards set by bodies like the FAA and EASA to guarantee an aircraft is safe and fit for flight.

- Maximizing Operational Efficiency: Minimizing unscheduled downtime, reducing flight delays, and optimizing maintenance schedules to keep aircraft flying and profitable.

- Extending Aircraft Lifespan: Implementing strategic maintenance programs that preserve the structural integrity and performance of aircraft, even as fleets age.

- Enhancing Safety: Proactively identifying and addressing potential issues before they escalate, preventing in-flight malfunctions and ensuring passenger and crew safety.

- Cost Management: Balancing the need for thorough maintenance with the imperative to control operational costs for airlines and MRO (Maintenance, Repair, and Overhaul) providers.

The Digital Revolution in the Hangar: Key Technologies Shaping Maintenance

The days of purely manual inspections and reactive repairs are steadily fading. Today’s flight maintenance is increasingly data-driven, predictive, and proactive, thanks to a suite of innovative technologies:

- Predictive Maintenance (PdM) powered by AI and Machine Learning: This is the undisputed star of modern maintenance. Thousands of sensors on a modern aircraft generate terabytes of data per flight. AI and ML algorithms analyze this vast dataset – including vibration, temperature, pressure, and engine performance – to detect subtle anomalies and predict potential component failures before they occur. This allows maintenance to be scheduled precisely when needed, minimizing unplanned downtime and maximizing aircraft availability. Airlines are seeing significant reductions in unscheduled maintenance events and substantial cost savings.

- Internet of Things (IoT) and Cloud Computing: IoT sensors embedded throughout the aircraft collect real-time data on component health. This data is then transmitted to cloud-based platforms, where it’s stored, processed, and made accessible for analysis by maintenance teams globally. This ubiquitous connectivity is foundational to predictive maintenance.

- Augmented Reality (AR) and Virtual Reality (VR):

- Training: AR and VR are revolutionizing technician training. Immersive VR simulations allow aspiring engineers to practice complex repair procedures in a safe, virtual environment, reducing training time and costs.

- On-the-Job Support: AR headsets can overlay digital information (like step-by-step instructions, diagrams, or component specifications) directly onto the physical aircraft, guiding technicians through intricate tasks, reducing errors, and improving efficiency. Remote experts can also provide real-time guidance to on-site technicians through AR.

- Drones and Robotics for Inspections: Tedious and time-consuming visual inspections, especially of hard-to-reach areas like wings and fuselages, are being transformed by drones. Equipped with high-resolution cameras and AI-powered visual recognition software, drones can quickly scan an aircraft for cracks, dents, and corrosion, providing detailed reports in a fraction of the time a manual inspection would take. More advanced robots are even being developed to perform minor repairs.

- Digital Twins: A virtual replica of a physical aircraft, component, or system. Digital twins are continuously updated with real-time performance data, allowing maintenance teams to simulate different scenarios, predict component behavior, and optimize maintenance strategies without impacting the actual aircraft.

- Generative AI for Maintenance Support: Imagine a technician asking an AI “copilot” to troubleshoot an unfamiliar issue, instantly pull up relevant sections from maintenance manuals, or even automatically generate work orders and reports. Generative AI is set to significantly reduce research and administrative burdens, allowing technicians to focus more on hands-on work.

- Blockchain for Records Management: Ensuring the integrity and traceability of maintenance records and parts provenance is crucial. Blockchain technology offers a secure, immutable ledger for every maintenance activity and part used, enhancing compliance and trust.

Trends Shaping the Future of Flight Maintenance

As we look ahead, several key trends will continue to define the trajectory of flight maintenance:

- Increased Focus on Sustainability: Maintenance practices will increasingly incorporate eco-friendly materials, energy-efficient processes, and optimized waste management. The rise of electric and hybrid aircraft will also necessitate new maintenance skill sets.

- Addressing the Skills Gap: The rapid adoption of new technologies demands a highly skilled workforce. The industry is investing heavily in advanced training programs to equip technicians with the expertise in AI, data analytics, robotics, and new aircraft systems.

- Data Integration and Interoperability: The true power of these technologies lies in their ability to communicate and share data seamlessly. Future maintenance systems will prioritize integrated digital platforms that connect all aspects of MRO, from planning to execution and inventory.

- Personalized Maintenance: As data analysis becomes more sophisticated, maintenance schedules could become even more tailored to the individual operational profile and historical performance of each aircraft, moving beyond generic recommendations.

Conclusion:

Flight maintenance is no longer just about fixing planes; it’s about optimizing performance, ensuring continuous airworthiness, and leveraging intelligence to predict and prevent issues. The ongoing technological revolution is making aviation safer, more efficient, and increasingly sustainable. For airlines, MROs, and technology providers, embracing these innovations is not just a competitive advantage—it’s a commitment to the future of flight, ensuring that the skies remain a safe and reliable pathway for global connectivity. The journey of transforming flight maintenance has only just begun, promising a future of unprecedented precision and reliability in the air.